Frequently Asked Questions

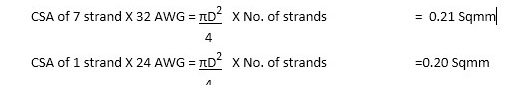

In AWG 24/7/32, 1st & 3rd number (24 & 32) show AWG sizes & 2nd number (7) shows number of strands. It means cross sectional area of 7 strands of 32 AWG is nearly equal single strand of 24 AWG.

If you require Solid conductor go with 24 AWG (0.51 mm dia.) If require same size in multistrand configuration then go with 7 strands of 32 AWG (0.204 mm)

Here 1st number shows no of strand in conductor & 2nd number shows conductor size. Like for 3/22 SWG , here number of strand in conductor is 3 & each strand dia is 22 SWG (0.71 mm). So cross sectional area would be as under

The ambient temperature where the cable has to be laid is below 100 °C compensating cable is used. At 100 °C both compensating conductor (Copper alloy) & extension conductors (Nickel alloys) exhibits same accuracy according to ANSI MC 96.1 / IEC 60584.3. Compensating conductors are much cheaper than extension conductors so for below 100 °C compensating cable should be used. The ambient temperature where the cable has to be laid is above 100 °C extension cable is used. Thermocouple original conductor cable is used for critical applications where a slight change of temperature affects much.

In R type (Pt Rh-13% & Pt) & S type (Pt Rh-10% & Pt) thermocouple there is only difference of % of Pt in positive conductor material. So compensating cable made with Copper (+) copper alloy (-) conductors are commonly used to extend the thermocouple signal for both R & S type. Hence both cables (R & S type) are same, only known as R/S type compensating cable from the name of thermocouple for which cable would be used.

Thermocouple cable output comes in milivolts, so resistance of any thermocouple cable does not effect on its output.

Yes, PTFE, all other fluoropolymer (FEP, ETFE,X-ETFE, PFA), PEEK, Silicon,fiber glass having halogen free compound. These materials have max HCL Acid gas emission value of 0.5 %.

Yes, PTFE & all other fluoropolymer (FEP, ETFE,X-ETFE, PFA) exhibit FRLS properties. These all materials are self extinguished.

Oxygen index value for PTFE is > 95 % that is far better than thermoplastic, thermosetting & elastomeric compound.

Smoke density rating for PTFE insulation is max 20 %, whereas normal thermoplastic FRLS material having smoke density rating 60 % max.

Plated copper such as Silver plated copper, nickel plated copper & tin plated copper are used at place of bare copper to prevent the conductor from corrosion, for providing excellent heat resisting & conductive properties. Also use of plated copper conductors are depend on cables applications as silver plated copper is used for high frequency application whereas nickel plated copper conductors are used in high temperature wire & heating applications.

Current flow at the outer surface of the conductor, silver plated copper have the highest conductivity, resulting lowest voltage drop. So signal transmission would be faster & with minimize loss than other conductors. Also current rating is higher than normal conductor so for higher current rating we need to select lower conductor size result in light weight cable for ease installation. Beyond these above characteristics silver plated copper have excellent Solderability properties than others.

Whatever conductor size you require having the same accuracy within the limit according to IEC 60584.3. So size does not affect the accuracy of conductor.

- Instrumentation cable usually comes in pair or triad construction whereas control cable generally in multicore design.

- Usually instrumentation cables have maximum conductor size 1.50 Sqmm & in control cables it’s 2.50 Sqmm.

- Instrumentation cables are recommended with screening, whereas in control cable it’s upon customer’s requirement

AWG (American wire gauge)

SWG (Standard wire gauge), both are wire size gauges. Gauge Conversion table in inches & mm are given such as 32 AWG ( 0.20 mm), 32 SWG (0.274 mm)

.Regular size used in thermocouple cables are as under

- 7X36 SWG (0.22 Sqmm)

- AWG 24/7/32 ( 0.22 Sqmm)

- 20 AWG (0.50 Sqmm)

- 7 X 0.30 mm (0.50 Sqmm)

- 3/22 SWG (1.19 Sqmm)

- 1/16 AWG (1.30 Sqmm)

- 18 AWG (0.81 Sqmm)

- 0.75 Sqmm ,1.00 Sqmm & 1.50 Sqmm.

Mostly 1.50 Sqmm is the highest conductor size used in thermocouple cable.

- 7/36 SWG (0.22 Sqmm)

- 7/32 SWG (0.42 Sqmm)

- 7/0.30 mm (0.50 Sqmm)

- 24/0.20 mm (0.75 Sqmm)

- 1.0 sqmm & 1.50 Sqmm

Yes, PTFE, all other fluoropolymer (FEP, ETFE,X-ETFE, PFA), PEEK, Silicon,fiber glass having halogen free compound. These materials have max HCL Acid gas emission value of 0.5 %.

Yes, PTFE & all other fluoropolymer (FEP, ETFE,X-ETFE, PFA) exhibit FRLS properties. These all materials are self extinguished.

Oxygen index value for PTFE is > 95 % that is far better than thermoplastic, thermosetting & elastomeric compound.

Smoke density for PTFE insulation is max 20 %, whereas normal thermoplastic FRLS material having smoke density rating 60 % max.

Plated copper such as Silver plated copper, nickel plated c copper, tin plated copper are used at place of bare copper to prevent the conductor from corrosion, for providing excellent heat resisting & conductive properties. Also use of plated copper conductors are depend on cables applications as silver plated copper is used for high frequency application whereas nickel plated copper conductors are used in high temperature wire & heating applications.

Current flow at the outer surface of the conductor, silver plated copper have the highest conductivity, resulting lowest voltage drop. So signal transmission would be faster & with minimize loss than other conductors. Also current rating is higher than normal conductor so for higher current rating we need to select lower conductor size result in light weight cable for ease installation. Beyond these above characteristics silver plated copper have excellent Solderability properties than others.