ELECTROPLATED COPPER WIRES

August 30, 2018

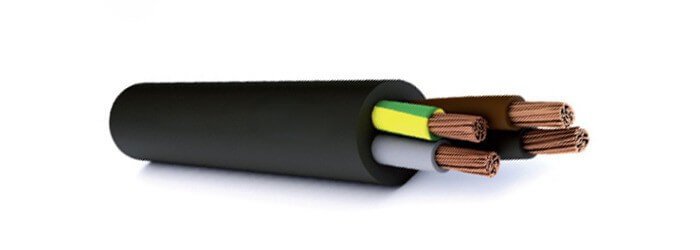

Fire Resist Cables

August 31, 2018EPR INSULATED CABLES

We are providing EPR Insulated fire resist cable, trailing cables & customized cables. Trailing cables are used for high mechanical stress, especially in applications with frequent winding and unwinding with simultaneous tensile and torsion stress. These cables are frequently used in building machinery, conveyors, lifting systems and cranes with almost every industry segment like Steel Mills, Cement plants, Docks, Power Plants, Automobile Industries & Refineries and Petrochemicals.

Beyond These EPR Insulated Cables we are also providing Neoprene Rubber Cable & TRS Insulated Cables.

Types of Cables provided from these above insulations:

A) Fire Resist Cables :

EPR Insulated cable are designed to work under Fire conditions. These Fire resistance cables are complying to BS7629-1 IEC 60331 standard.

In this Fire resistance cable Glaa Mica + EPR rubber is used over conductor to perform cable under fire circumstances.

B) Trailing Cables :

Trailing cables are also manufactured with EPR insulation over conductor, in this sheath shall be used as PCP, HOFR PCP and othe quality rubber insulation.

C) Composite Cables :

EPR Insulated composite cables are also manufactured where signal, power & control cables assembly required over rated temperature

of 90 Deg C. Flexibility is also major key to use EPR Insulation in customized cable

Features of EPR Insulated Cables:

- High tensile strength

- Flexible

- Max conductor temperature 90°C for continues use & 250°C for short term use

- Comply to IS 9968 & international standard Chemical resistant

- Water resistance

- Durable

- Fine finish