(H-TEMP-C005) PTFE TWISTED

August 7, 2018(H-TEMP-C012) FIBER GLASS-FIBER GLASS-SS BRAIDING

August 7, 2018

(H-TEMP-C006) PTFE-ALMYLAR SCREEN-PTFE

Technical Details

| Design Standard |

As per JSS 51034, JSS 51038, MIL 16878 & IS 8130 |

| Conductor |

Annealed Bare Copper/Silver Plated Copper/Nickel Plated Copper |

| Conductor Type |

Solid wire / Flexible |

| Conductor Size |

0.50/0.75/1.0/1.5/2.5 or variant as per customer specifications |

| Insulation |

Wrapped & Sintered PTFE |

| Core Identification |

By different colour & colour tracer |

| Screening |

Almylar tape screening along with tinned copper drain wire with 100% Coverage Area |

| Outer Sheath |

Wrapped & Sintered PTFE |

| Colour Availability |

Black, Blue, Black, Grey, Red or as per your requirement |

| Voltage Grade |

300V / 600 V / 1100 V |

| Tested Voltage |

- 1500 V for 300 Voltage Grade

- 2000 V for 600 Voltage Grade

- 3000 V for 1000 Voltage Grade

|

| Temperature Range |

-65 Deg C to 260 Deg C |

Applications:

- For Signal & Data Transmission used in measurement & control technology in high temperature zone

- Analogue & Digital signal transmission

- Industry plant, power station, refineries, petrochemical plants etc.

- Industry plant, power station, refineries, petrochemical plants etc.

- In Defence, Aerospace, Pharma, Fertilizer, Glass , Steel & Sponge, Cement, Nuclear & many more sectors.

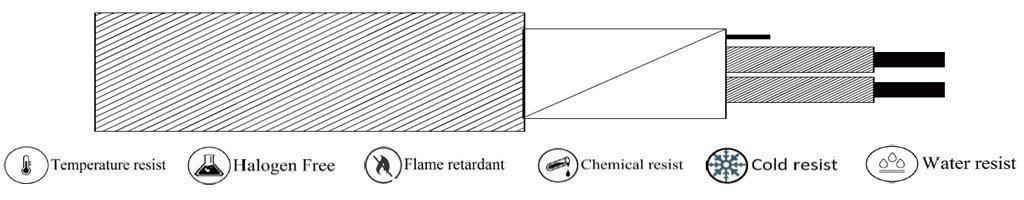

Features:

- Flame & Fire Resistance

- Temperature range up to 260 Deg C

- Shielding to reduce the electrical noise & external electromagnetic interference

- Halogen Free & Low smoke

- Enhance thermal, electrical & fire properties

- Good Flexibility

- Excellent Dielectric Strength

- Excellent Insulation resistance

- Good abrasion resistance

- Chemical & Oil Resistance